Embarking on the journey to repair and rebuild an old car engine can be a rewarding yet challenging endeavor. Whether you’re a seasoned mechanic or a passionate car enthusiast, this guide will walk you through the process step by step, providing valuable tips and tricks to breathe new life into your vintage vehicle.

Understanding the Basics

Before you embark on the journey of rebuilding, it’s crucial to identify the types of engine your classic car houses. There are various engine types, such as inline, V-shaped, and rotary. Each comes with its own set of challenges and nuances during the rebuilding process.

Assessing the Damage

Old car engines often suffer from wear and tear, rust, and other issues. Begin by inspecting the engine block, cylinder heads, and pistons. Look out for cracks, leaks, or any signs of corrosion. This step sets the stage for a targeted and effective rebuild.

Gathering the Right Tools

A successful engine rebuild requires precision and the right set of tools. From socket wrenches to torque wrenches, having the correct tools at your disposal ensures a seamless process. Don’t forget safety gear – goggles, gloves, and a well-ventilated workspace are non-negotiable.

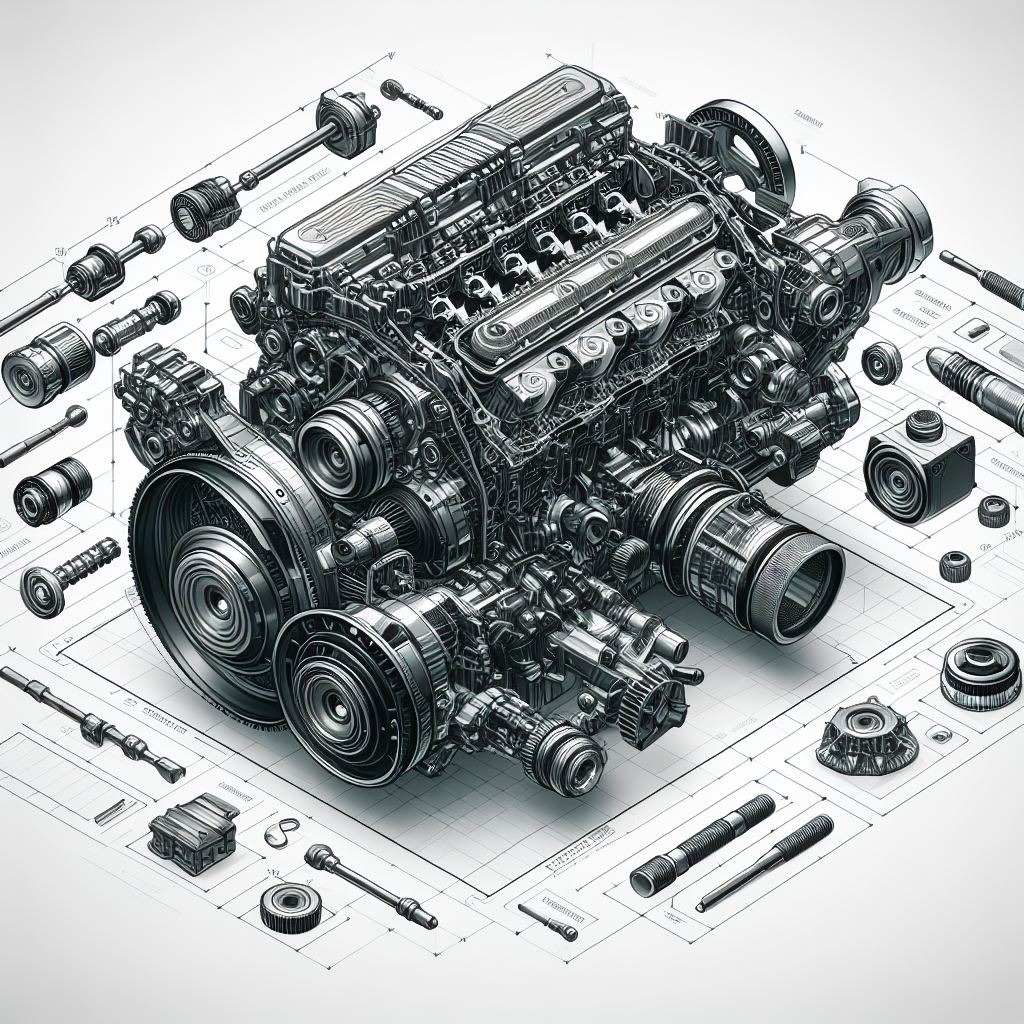

Disassembling the Engine

Divide and conquer – this philosophy applies perfectly to the engine rebuild process. Begin by removing the external components, then move on to disassembling the internal parts. Take note of the arrangement, as this will aid you during reassembly.

Cleaning and Preparing Parts

A clean engine is a happy engine. Use a combination of solvents, brushes, and compressed air to remove dirt, grime, and old gaskets. Take your time with this step; a well-cleaned engine is the foundation of a successful rebuild.

Replacing Worn-Out Parts

Identify parts that show signs of excessive wear or damage. From gaskets to bearings, investing in high-quality replacement parts is crucial. This not only enhances the engine’s performance but also ensures longevity.

Machining and Resurfacing

Engage the services of a reputable machine shop to resurface cylinder heads and engine blocks. Precision machining is the key to achieving the ideal surface finish, promoting better sealing and overall engine efficiency.

Reassembly with Care

Now comes the exciting part – reassembling the engine. Follow the reverse order of disassembly, referring to your notes and photographs. Ensure that everything fits snugly, applying the right torque to bolts and fasteners.

Testing and Tuning

Before declaring victory, conduct a series of tests to ensure everything is in working order. Check for leaks, strange noises, and irregularities. Once satisfied, fine-tune the engine for optimal performance.

Tips for a Successful Engine Rebuild

- Patience is a Virtue: Rome wasn’t built in a day, and neither is a perfectly rebuilt old car engine. Take your time, and the results will be worth it.

- Document Everything: From the disassembly process to torque settings, meticulous documentation will be your guide during reassembly.

- Consult Experts: If in doubt, don’t hesitate to seek advice from experienced mechanics or online forums. Their insights can prove invaluable.

Conclusion

Rebuilding an old car engine is not just a mechanical task; it’s a labour of love. By following these tips and tricks, you’ll not only revive a piece of automotive history but also gain a profound sense of accomplishment. Happy rebuilding!

FAQs

Q: What are the common signs that indicate my old car engine needs rebuilding?

A: Look out for excessive smoke, poor fuel efficiency, and unusual noises like knocking or tapping.

Q: How do I determine the type of engine in my classic car?

A: Identify the arrangement of cylinders – inline, V-shaped, or rotary – by visually inspecting the engine.

Q: Can I rebuild my old car engine without professional help?

A: Yes, it’s possible with the right tools, knowledge, and patience, but seeking professional advice is recommended.

Q: What safety precautions should I take during the engine rebuilding process?

A: Wear goggles and gloves, work in a well-ventilated area, and follow proper tool usage guidelines.

Q: Is it necessary to replace all worn-out parts during an engine rebuild?

A: Replace critical components like gaskets and bearings, but prioritize based on wear severity and budget constraints.

Q: How often should I test and tune the rebuilt engine for optimal performance?

A: Conduct initial tests after assembly, then fine-tune and test periodically, especially after the first few hundred miles.

Stay in touch to get more updates & alerts on Washington Greek! Thank you