In the area of metallic fabrication, precision is paramount. Whether it is intricate patterns, complex shapes, or tight tolerances, attaining accuracy is essential for generating superb metallic components. Laser slicing generation has emerged as a sport-changer in this regard, supplying unprecedented precision and flexibility in reaching complicated metallic sheet designs.

In this article, we are able to explore the pivotal function of laser reduction in precision engineering, inspecting its skills, benefits, and applications in attaining difficult metal sheet designs.

Understanding Laser Cutting Technology

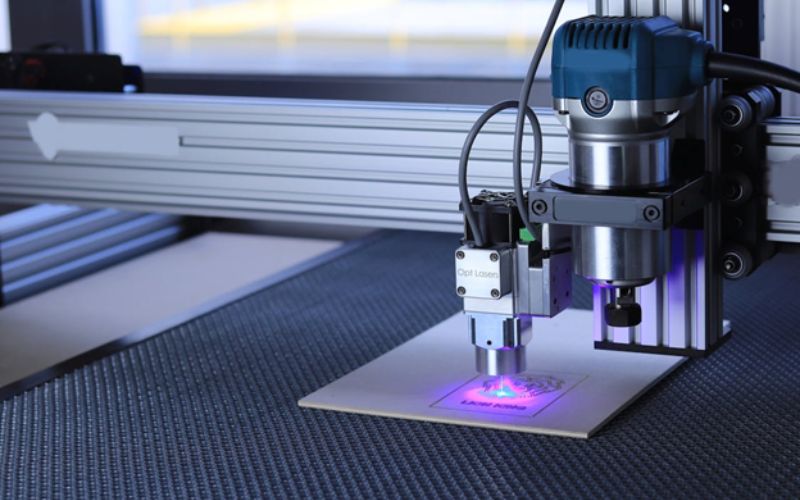

Laser cutting is a thermal-based totally machining system that utilizes an excessive-powered laser beam to precisely cut via materials, consisting of metal sheets, with exceptional accuracy. The procedure involves focusing the laser beam onto the workpiece, inflicting localized heating and vaporization of the cloth. As the laser cutting machine takes the actions along the programmed cutting course, it melts and evaporates the metal, developing a slender kerf with minimum heat-affected zones.

Advantages of Laser Cutting for Precision Engineering

Unparalleled Precision: Laser slicing generation offers unmatched precision in achieving problematic steel sheet designs. With beam diameters as small as a few thousandths of an inch, laser cutters can produce intricate capabilities and tight tolerances with extraordinary accuracy.

Versatility: Laser cutting is surprisingly flexible and can accommodate a huge variety of metallic substances, together with stainless-steel, aluminum, copper, and titanium. It can reduce via various thicknesses of metal sheets, from skinny foils to thick plates, without compromising precision or high-quality.

Minimal Material Waste: Unlike traditional machining methods such as milling or stamping, which produce substantial quantities of scrap material, laser slicing minimizes cloth waste. The narrow kerf width and unique slicing path of the laser beam result in minimal fabric loss, maximizing fabric utilization and decreasing prices.

Complex Geometries: Laser slicing generation permits the fabrication of complex geometries and tricky designs that could be challenging or not possible to acquire with conventional machining strategies. From tricky filigree patterns to particular equipment teeth, laser cutters provide extraordinary flexibility in growing elaborate metal sheet designs.

Rapid Prototyping: Laser reduction enables speedy prototyping of metal additives, permitting engineers and designers to quickly iterate and refine their designs. With the ability to translate digital designs immediately into bodily prototypes, laser reduction speeds up the product improvement cycle and reduces time-to-market.

Applications of Laser Cutting in Precision Engineering

Aerospace and Defense: In the aerospace and defense industries, in which precision and reliability are paramount, laser slicing generation is extensively used for fabricating plane components, missile components, and defense structures. Laser-reduced steel sheets are utilized in plane fuselage panels, engine additives, and structural reinforcements, ensuring uncompromising great and overall performance.

Automotive Manufacturing: Laser reduction performs a critical role in car manufacturing, in which precision is essential for generating notable vehicle additives. Laser-cut metal sheets are utilized in body panels, chassis elements, and interior trim pieces, allowing automakers to achieve tight tolerances and superior fitment in their vehicles.

Electronics and Technology: In the electronics and technology sectors, wherein miniaturization and precision are key drivers, laser slicing technology is used for fabricating steel additives for digital devices, telecommunications equipment, and consumer electronics. Laser-reduced metal sheets are used in cellphone chassis, pc enclosures, and microelectronic additives, making precise dimensions and elaborate capabilities.

Medical Device Manufacturing: Laser slicing is widely hired inside the fabrication of scientific gadgets and surgical instruments, where precision and cleanliness are vital requirements. Laser-cut metal sheets are utilized in implantable scientific gadgets, diagnostic devices, and surgical contraptions, ensuring unique dimensions and biocompatibility.

Architectural Metalwork: Laser reducing era is used in architectural metalwork for creating intricate designs, decorative elements, and structural components. Laser-cut metallic sheets are used in building facades, interior partitions, and ornamental functions, permitting architects and architects to recognize their creative visions with precision and elegance.

Conclusion

Laser reducing generation has revolutionized precision engineering, allowing the fabrication of complicated metallic sheet designs with extraordinary accuracy and flexibility. From aerospace additives to digital gadgets, laser-cut metallic sheets locate programs across a huge variety of industries, riding innovation and development in production. As technology keeps developing, laser reduction will continue to play a pivotal function in precision engineering, pushing the boundaries of what’s possible in metal fabrication.