Engineering, and manufacturing, steel fabrication stands as a cornerstone process, facilitating the creation of sturdy structures and vital components across various industries. From towering skyscrapers to intricate machinery, steel fabrication Houston shows an essential role in shaping the modern world. But what exactly is steel fabrication, and why is it so crucial?

Let’s delve deep into this fascinating realm to uncover essential facts that everyone should know.

What is Steel Fabrication: A Brief Overview

At its core, steel fabrication is the process of transforming raw steel materials into predefined shapes, sizes, and structures through cutting, bending, assembling and welding company Houston. This intricate process involves a combination of skilled labour, advanced machinery, and meticulous planning to produce high-quality steel products tailored to specific requirements.

Key Components of Steel Fabrication

Design and Planning: The journey of steel fabrication begins with meticulous planning and design. Engineers and designers collaborate to conceptualize the structure or component, considering factors such as load-bearing capacity, functionality, and aesthetic appeal.

Material Selection:

Steel, renowned for its strength, durability, and versatility, is the primary material used in fabrication. Various grades of steel are available, each suited to different applications based on factors like corrosion resistance, tensile strength, and ductility.

Cutting:

Once the design is finalized, the raw steel undergoes cutting to achieve the desired shape and dimensions. Traditional methods like sawing and shearing have given way to advanced techniques such as laser cutting and plasma cutting, offering greater precision and efficiency.

Forming and Shaping:

Bending and shaping processes are employed to mold the steel into the required configurations. This may involve techniques like rolling, pressing, or forging, depending on the complexity of the design and the properties of the steel.

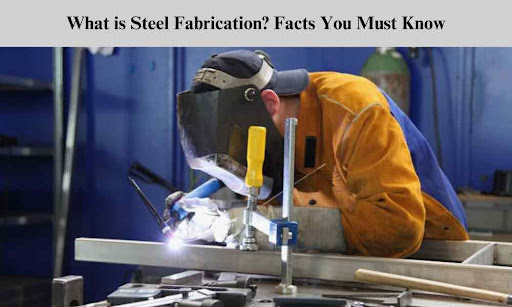

Welding and Joining:

Welding is a serious aspect of steel fabrication, where individual pieces are fused together to create a cohesive structure. Skilled welders use various welding techniques such as arc welding, MIG welding, and TIG welding to achieve strong and durable bonds.

Surface Treatment and Finishing:

Surface treatment techniques like sandblasting, painting, and galvanizing are employed to enhance the appearance and durability of fabricated steel products. These treatments provide protection against corrosion, abrasion, and environmental factors.

Quality Assurance:

Throughout the fabrication process, stringent quality control measures are implemented to ensure that the finished products meet the highest standards of safety, performance, and reliability. This involves inspections, testing, and adherence to industry regulations and standards.

Applications of Steel Fabrication

The versatility of steel fabrication makes it indispensable across a wide range of industries and applications:

Construction:

Steel fabricated components form the backbone of modern construction projects, including bridges, buildings, and infrastructure. The strength-to-weight ratio of steel makes it ideal for constructing large, durable structures that can withstand environmental forces.

Manufacturing:

In the manufacturing sector, steel fabrication is essential for producing machinery, equipment, and industrial components. From automotive parts to machinery frames, fabricated steel plays a vital role in driving manufacturing processes.

Transportation:

Steel fabrication contributes to the transportation sector by manufacturing components for vehicles, ships, and aircraft. Steel’s durability and resilience make it an ideal choice for applications where safety and reliability are paramount.

Energy and Utilities:

The energy and utilities industry relies on steel fabrication for constructing power plants, pipelines, and infrastructure. Steel’s resistance to high temperatures and harsh environments makes it indispensable for such critical applications.

The Future of Steel Fabrication

As technology continues to advance, the field of steel fabrication is poised for further innovation and evolution. Automation, robotics, and digitalization are transforming traditional fabrication processes, enhancing efficiency, precision, and sustainability. Additionally, the growing emphasis on sustainability and environmental responsibility is driving the adoption of eco-friendly practices and materials in steel fabrication.

Conclusion

Steel fabrication is a multifaceted process that lies at the heart of numerous industries and applications. From conception to completion, the journey of transforming raw steel into functional structures and components requires expertise, precision, and innovation. By understanding the essential facts about steel fabrication, we gain a deeper appreciation for its significance in shaping the modern world and driving progress across various sectors.

Top of Form

Frequently Asked Questions About Steel Fabrication

What is steel fabrication?

Steel fabrication is the process of transforming raw steel materials into predefined shapes, sizes, and structures through cutting, bending, welding, and assembling. It involves a combination of skilled labor, advanced machinery, and meticulous planning to produce high-quality steel products tailored to specific requirements.

What types of materials are used in steel fabrication?

Steel is the primary material used in fabrication due to its strength, durability, and versatility. Various grades of steel are available, each suited to different applications based on factors like corrosion resistance, tensile strength, and ductility.

How is quality ensured in steel fabrication?

Quality assurance in steel fabrication involves stringent measures such as inspections, testing, and adherence to industry regulations and standards. Skilled professionals oversee each stage of the fabrication process to ensure that the finished products meet the highest standards of safety, performance, and reliability.

What is the future of steel fabrication?

The future of steel fabrication is characterized by technological advancements such as automation, robotics, and digitalization, which enhance efficiency, precision, and sustainability. Additionally, there is a growing emphasis on eco-friendly practices and materials in response to environmental concerns.

What are the key components of steel fabrication?

Design and Planning

Material Selection

Cutting

Forming and Shaping

Welding and Joining

Surface Treatment and Finishing

Quality Assurance