Protective packaging plays a vital role in safeguarding products during transportation and storage, ensuring they reach customers in pristine condition. In today’s dynamic marketplace, where customer satisfaction and brand reputation are paramount, investing in effective protective packaging solutions is non-negotiable. From fragile electronics to delicate glassware, the right packaging can mean the difference between a satisfied customer and a damaged shipment.

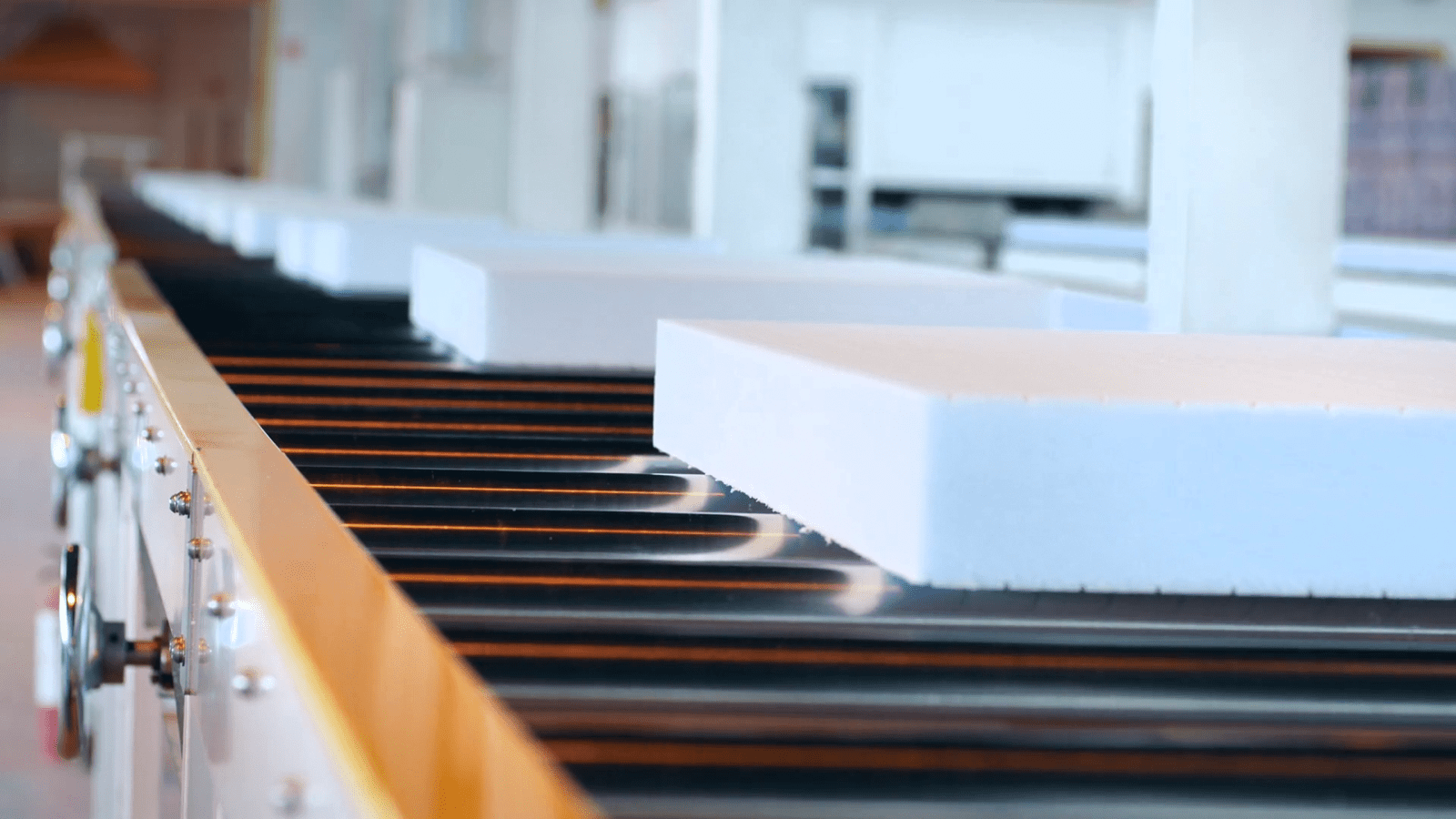

In the realm of logistics and e-commerce, Protective packaging serves as the armor that shields products from the perils of the supply chain. Defined as the materials and techniques used to safeguard goods from damage, protective packaging encompasses a wide array of solutions tailored to meet the unique requirements of different products and industries. Its significance extends beyond mere protection; it is a strategic imperative for businesses seeking to deliver exceptional customer experiences.

Importance of Protective Packaging

Ensuring Product Safety

At its core, protective packaging is about preserving the integrity of products from the point of manufacture to the hands of the end consumer. Whether it’s shielding delicate electronics from impact or preventing leakage in liquid products, the primary objective is to ensure that goods arrive in the same condition as when they left the production facility.

Minimizing Damage during Transit

The journey from warehouse to doorstep is fraught with potential hazards, including rough handling, temperature fluctuations, and environmental factors. Protective packaging acts as a buffer against these threats, absorbing shocks and vibrations to prevent breakage, dents, and scratches.

Enhancing Brand Image

Beyond its functional role, protective packaging also serves as a tangible representation of a brand’s commitment to quality and customer satisfaction. Well-designed packaging not only instills confidence in the product but also creates a memorable unboxing experience that fosters brand loyalty.

Types of Protective Packaging Materials

The diversity of products necessitates a diverse range of packaging materials, each offering unique properties suited to specific applications.

Bubble Wrap

Arguably the most iconic of all protective packaging materials, bubble wrap consists of air-filled bubbles encapsulated in a plastic sheet. Its cushioning properties make it ideal for fragile items such as glassware, electronics, and ceramics.

Foam Packaging

Foam packaging, available in various forms including foam sheets, blocks, and custom-molded inserts, provides excellent shock absorption and vibration dampening. It is commonly used for high-value or sensitive products requiring a high level of protection.

Cardboard Boxes

While seemingly simple, cardboard boxes remain a staple in protective packaging due to their versatility and cost-effectiveness. Corrugated cardboard offers strength and durability while being lightweight and recyclable.

Air Pillows

Air pillows, made from durable polyethylene film, provide lightweight cushioning and void fill. They are particularly useful for filling empty spaces within packages to prevent movement and shifting during transit.

Packing Peanuts

Made from expanded polystyrene or biodegradable materials, packing peanuts fill voids and provide cushioning in packages. Their interlocking shape ensures stability and prevents settling.

Protective Sleeves

Designed to envelop and protect individual items such as bottles, tubes, and cylindrical objects, protective sleeves offer an additional layer of security against scratches and abrasions.

Factors to Consider When Choosing Protective Packaging

Selecting the appropriate protective packaging requires careful consideration of various factors to ensure optimal protection and cost-effectiveness.

Nature of the Product

Understanding the characteristics of the product, including its fragility, shape, and dimensions, is essential in determining the most suitable packaging solution.

Fragility

Products with delicate components or sensitive surfaces require packaging materials with superior cushioning and shock-absorbing properties to prevent damage.

Weight and Size

The weight and size of the product influence the choice of packaging materials, as heavier items may require sturdier packaging to withstand the rigors of transportation.

Shipping Conditions

Consideration must be given to the shipping method and the potential hazards associated with it, such as rough handling, temperature variations, and exposure to moisture.

Environmental Considerations

In an increasingly eco-conscious world, selecting packaging materials that are recyclable, biodegradable, or made from sustainable sources is not only socially responsible but also aligns with consumer preferences.

Benefits of Using Protective Packaging

The adoption of effective protective packaging offers a multitude of benefits for businesses and consumers alike.

Reducing Returns and Exchanges

By minimizing product damage during transit, protective packaging helps reduce the incidence of returns and exchanges, saving businesses time, money, and resources.

Cost Savings

While investing in quality packaging may incur upfront costs, the long-term savings resulting from reduced product damage, fewer returns, and enhanced customer satisfaction far outweigh the initial investment.

Customer Satisfaction

A positive unboxing experience, facilitated by well-designed and protective packaging, enhances customer satisfaction and fosters brand loyalty, driving repeat purchases and positive word-of-mouth recommendations.

Trends in Protective Packaging

The landscape of protective packaging is continually evolving, driven by technological advancements, consumer preferences, and industry innovations.

Sustainable Packaging Solutions

As environmental concerns take center stage, there is a growing demand for sustainable packaging alternatives, such as recyclable materials, biodegradable packaging, and compostable plastics.

Customization and Personalization

In an era of personalization, brands are leveraging advanced printing technologies and customizable packaging designs to create unique and memorable unboxing experiences that resonate with consumers.

Integration of Technology

The integration of smart packaging technologies, such as RFID tags, QR codes, and temperature sensors, enables real-time tracking, authentication, and quality control throughout the supply chain.

Case Studies

Examining real-world examples of successful implementation of protective packaging provides valuable insights into best practices and innovative solutions.

Tips for Effective Use of Protective Packaging

Maximizing the effectiveness of protective packaging requires attention to detail and adherence to best practices.

Proper Packing Techniques

Employing proper packing techniques, including cushioning, bracing, and sealing, ensures that products remain secure and intact during transit.

Utilization of Fillers

Using appropriate fillers, such as bubble wrap, packing peanuts, or air pillows, helps fill empty spaces within packages and prevents movement and shifting.

Secure Sealing

Ensuring secure sealing with high-quality tape or adhesives prevents accidental openings and tampering, maintaining the integrity of the package.

Challenges in Protective Packaging

Despite its benefits, protective packaging is not without its challenges, ranging from environmental concerns to cost constraints and technological limitations.

Environmental Impact

The proliferation of single-use plastics and non-recyclable packaging materials contributes to environmental pollution and resource depletion, necessitating a shift towards more sustainable alternatives.

Cost Constraints

Balancing the need for effective protection with cost considerations poses a challenge for businesses, particularly small and medium-sized enterprises with limited budgets.

Innovation and Adaptation

As consumer preferences and industry regulations evolve, there is a constant pressure on businesses to innovate and adapt their packaging strategies to remain competitive and compliant.

Future Outlook of Protective Packaging

Looking ahead, the future of protective packaging is characterized by innovation, sustainability, and strategic partnerships.

Innovations in Materials

Advancements in material science are driving the development of novel packaging materials with enhanced strength, flexibility, and eco-friendliness.

Sustainability Initiatives

Industry-wide initiatives aimed at reducing waste, promoting recycling, and adopting circular economy principles are reshaping the landscape of protective packaging.

Industry Growth Projections

With the continued growth of e-commerce and globalization, the demand for protective packaging solutions is expected to surge, presenting lucrative opportunities for manufacturers, suppliers, and logistics providers.

Conclusion

Protective packaging serves as a cornerstone of modern commerce, ensuring the safe and secure transportation of goods from point of origin to final destination. By investing in effective packaging solutions and embracing sustainability, businesses can mitigate risks, enhance customer satisfaction, and drive long-term success in an increasingly competitive marketplace.